RESEARCH

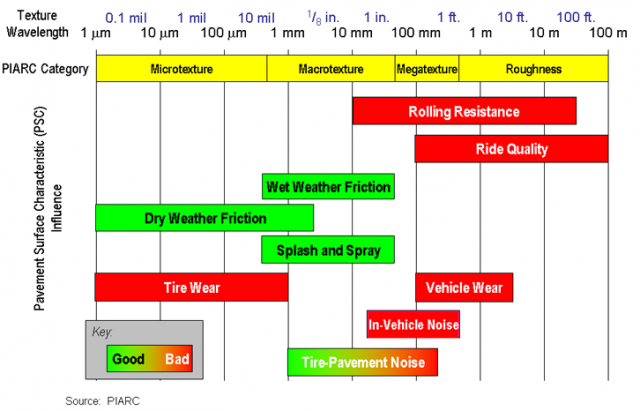

Pavement texture is often categorized by texture wavelengths (the length between physically repeating features). A pavement surface is often a combination of numerous wavelengths, ranging from microscopic (sub-millimeter) to long (several centimeters). The categories for texture wavelengths include megatexture (50 to 500 mm), macrotexture (0.5 to 50 mm), and microtexture (< 0.5 mm). Smoothness is partly contributed to by megatextures, tire-pavement noise by mega and macrotextures. Skid resistance, however, may be contributed to by all three, especially microtexture.

Traditionally, a Sand Patch Method has been used to estimate the degree of texture termed the Mean Texture Depth (MTD). MTD can be also be estimated from other types of equipment including laser-based devices. One such device, termed a Circular Texture Meter (CTM), is gaining popularity due to its ability to capture directional texture properties (commonly noted on concrete pavement surfaces that are tined or ground). There are numerous US and international standards available to characterize pavement textures and to measure skid resistances.

One additional pavement surface characteristic that has recently received attention includes the rolling resistance of a vehicle, which ultimately drives fuel consumption. Pavement texture is one driver behind this effect.

How are pavement textures characterized?

In order to characterize different textures, one must first understand what pavement texture is and how to properly measure it. A pavement surface often consists of a combination of numerous “wavelengths” of texture – the length between physically repeating features. Below is a table and chart illustrating basic texture categories, their wavelengths, and the surface characteristics they affect.

| Understanding Texture Wavelengths | Length | Affects |

|---|---|---|

| Microtexture | < 0.5 mm | Skid resistance |

| Macrotexture | 0.5 to 50 mm |

Skid resistance Tire-pavement noise |

| Megatexture | 50 to 500 mm |

Skid resistance Tire-pavement noise Smoothness |

Several methods have been developed to measure mega and macrotextures. Traditionally, a Sand Patch Method has been used to estimate the Mean Texture Depth, or MTD. This method involves applying a determined amount of sand or glass beads onto a textured surface, and spreading the sand outward into a circle. The more texture a surface contains, the smaller the circle that is created.

Another option available is a Circular Texture Meter, or CTM. Like the Sand Patch, this technique involves taking measurements at discrete locations along the pavement. The CTM uses a spot laser mounted on a rotating arm. Once in place, the unit triggers a computer that rotates the arm and measures texture height for one complete revolution. The resulting trace can be used to estimate the MTD, if desired. CTM

Laboratory measurements are also available, where a core can be extracted from the pavement under inspection and X-ray Computed Tomography (XCT) or Projected Moiré Interferometry (PMI) can be used. Some of the most recent advancements in texture measurement, however, are line-laser based devices such as RoboTex. The sensor mounted on RoboTex is a state-of-the-art Selcom RoLine line sensor from LMI Technologies. RoboTex is a six-wheeled, remote controlled robot that provides three-dimensional texture information for pavement surfaces.

Developments like these help engineers, contractors and road owners understand and assess various pavement surface characteristics with greater precision.

CONTACT US

The Transtec Group engineers the best pavements in the world. Have a pavement problem? Give us a call—we’re good listeners.

© 2025 | The Transtec Group, Inc. | Privacy Policy