The Transtec Group used in-depth testing and analysis to uncover the causes of pavement distresses at the Cleburne Regional Airport and made recommendations to maximize cost savings while providing a safer, longer-lasting pavement.

Much of the airfield at Cleburne Regional Airport was exhibiting moderate to severe cracking with isolated failures, and the distress was severe enough that total reconstruction was initially considered. Transtec, in partnership with Parkhill to assist TxDOT Aviation, used geotechnical data, falling weight deflectometer (FWD) testing, and extensive analysis to isolate the root causes of the observed distresses.

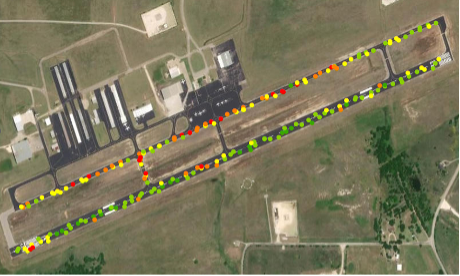

The airport’s 5,700-foot Runway 15/33, parallel Taxiway A, and cross Taxiway D indicated significant cracking so that the strength was in question. Transtec evaluated core samples of the pavement and performed FWD testing to backcalculate the stiffness of the runway and taxiways. FWD testing is non-destructive and provides detailed information about the quality of the pavement and subgrade. By using this technology, Transtec identified exact locations of the pavement damage and determined whether it was a surface-level distress or a more severe underlying issue. This information was essential in deciding whether the structure required full rehabilitation or if surface treatments and isolated repairs would suffice.

The extensive FWD testing that was performed reduced the required number of geotechnical boring locations and allowed the onsite investigation to be completed within an accelerated schedule. By using non-destructive testing and analysis methods, Transtec was able to evaluate the strength and stiffness of each pavement section, structural adequacy to support the anticipated aircraft loading, and determine the limits of problematic areas (even when not currently visible in the form of pavement distress). Overall, it was found that a majority of the observed cracking was not load-related but instead due to materials-related issues and environmental factors. Although, there were areas along the taxiways where structural improvement was recommended based on high deflections to allow for the estimated aircraft loading (see figure).

Based on the results of the field investigation, Transtec evaluated options for intervention that included reconstruction, rehabilitation with an overlay, or rehabilitation of the keel area with full depth reclamation (FDR). Construction details were developed and recommended to provide a long-lasting pavement with sufficient structural capacity, a durable surface resistant to deterioration, and smooth profile. Once implemented, they helped ensure a reduction in maintenance and future rehabilitation costs, which in turn will reduce both short- and long-term closures during the life of the airfield pavements.

This project was completed on time and on budget and has provided excellent performance for the past three years. One of the key takeaways related to this project is that with any approach, it is important to note that full reconstruction is not always necessary.

If you need assistance in determining why your pavement is failing and to identify ways to fix it, please call Transtec today.