PRECAST PAVEMENT

PRECAST PAVEMENT:

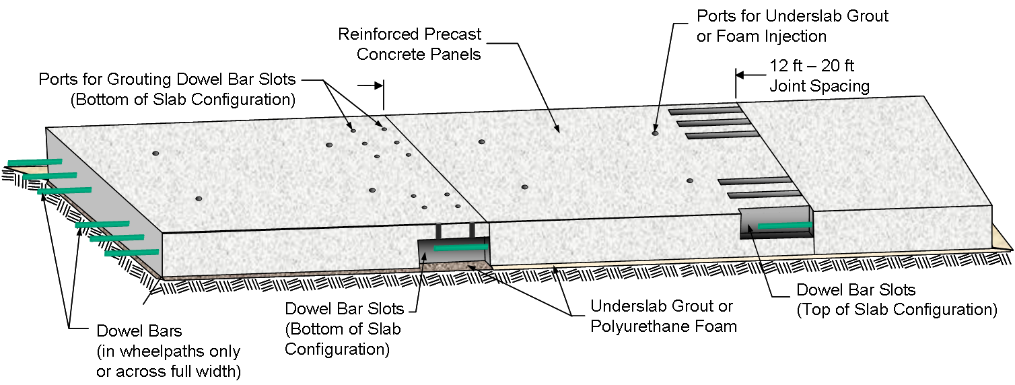

Jointed precast pavement systems consist of precast panels designed to expand and contract at each panel joint. It doesn’t require structural reinforcing steel for service loads but does need to be reinforced for handling and transportation. Jointed precast pavement system panels can also be reinforced by prestressing, leading to reduced panel thickness.

Jointed precast pavement systems are easily integrated with the surrounding pavements. The panels are sized and jointed to match the surrounding pavement, so the slabs will expand and contract similar to the surrounding preexisting pavement. Jointed precast pavement systems are also more easily fabricated than precast prestressed concrete pavement as there are no post-tensioning blockouts and prestressing ducts, which require precision to place to ensure constructability. In addition, jointed precast pavement systems are smaller and easier to transport.

Jointed precast pavement systems are the best option for intermittent repair applications and are also useful in continuous repairs of all lengths. They have successfully been used in the following applications:

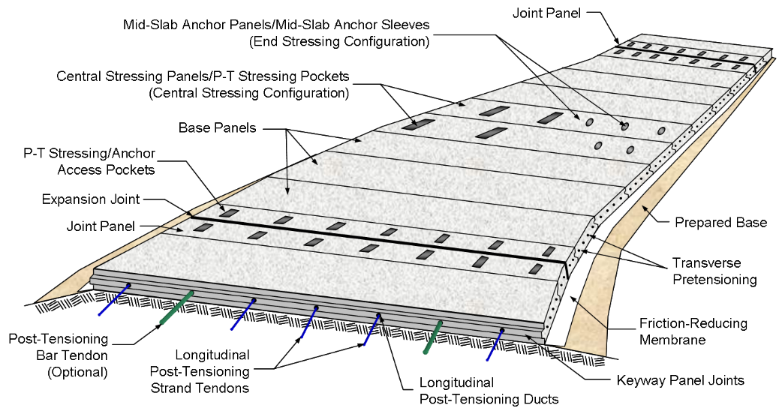

PPCP consists of precast panels tied together with post-tensioning after installation on the worksite. The pavement slab is prestressed in two directions, enhancing the structural characteristics of the panel, counteracting load and temperature-related stresses, and keeping joints tightly closed.

PPCP has a proven track record for reduced cracking, reduced slab thickness, and increased structural capacity. Prestressing helps compensate for nonuniformities in support which could be present before installing a base to fill small voids under the slabs. Prestressing also helps keep the joints between panel tightly closed, which can improve ride quality over each assembled slab.

CONTACT US

The Transtec Group engineers the best pavements in the world. Have a pavement problem? Give us a call—we’re good listeners.

© 2025 | The Transtec Group, Inc. | Privacy Policy