TESTING

Several factors affect highway safety including pavement friction, road geometry, traffic conditions, vehicle speed, and environmental conditions. Safety data shows low friction in conjunction with wet conditions directly correlates to increased number of skid related crashes. Thus, from a pavement engineering perspective, friction is a key factor in highway safety.

HFST is applied to existing pavement surfaces to significantly increase skid resistance at locations where friction demand is highest, such as at curves and near intersections. According to the video, agencies have experienced significantly reduced crash rates following HFST installations.

After 87 crashes occurred on a busy connector ramp in Wisconsin within just one year, HFST was installed on the pavement surface. FHWA and ATSSA report that only two crashes have been recorded at that site since the 2011 installation.

According to FHWA technical advisory, Pavement Friction Management (T 5040.38), June 17, 2010, the objective of a pavement friction management program is to minimize friction-related vehicle crashes and increase safety by:

Ensuring that new pavement surfaces are designed, constructed, and maintained to provide adequate and durable friction properties.

Transtec’s engineers understand pavement materials, mixtures, and construction methods. We can develop construction specifications to help ensure your project achieves suitable pavement friction properties.

Identifying and correcting sections of roadways that have elevated friction-related crash rates.

There are many ways to retexture an existing pavement to increase friction; grinding, grooving, shot peen, overlay, application of a high friction surface, and more. But, which one is the best choice? Transtec can recommend retexturing methods optimized to your roadway and situation.

Prioritizing use of resources to reduce friction-related vehicle crashes in a cost-effective manner.

Transtec can assist with your network level resource optimization. Our expertise in materials, pavements, and textures make us uniquely qualified to provide additional value to the recommendations in the AASHTO Guide for Pavement Friction, 2008.

An exit ramp was recently rehabilitated using our agency’s standard mix. But, now the accident rate on the ramp is much higher than expected. Why? And, how do I fix it?

Transtec pavement experts can help you investigate the root cause for low pavement friction conditions on roadways or airport runways and develop optimized corrective actions to improve safety.

How do I specify the materials or methods to achieve targeted pavement friction levels?

Transtec’s engineers understand pavement materials, mixtures, and construction methods. We can develop construction specifications to help ensure your road or airport runway project achieves suitable pavement friction properties and safety levels.

GripTester is the accurate and economical way to measure skid resistance. Ensure your pavements are providing adequate friction year-round. Transtec’s GripTester services help you maintain a dependable pavement system.

GripTester is the accurate and economical way to measure skid resistance on airport runways.

GripTester is the accurate and economical way to measure skid resistance on roads.

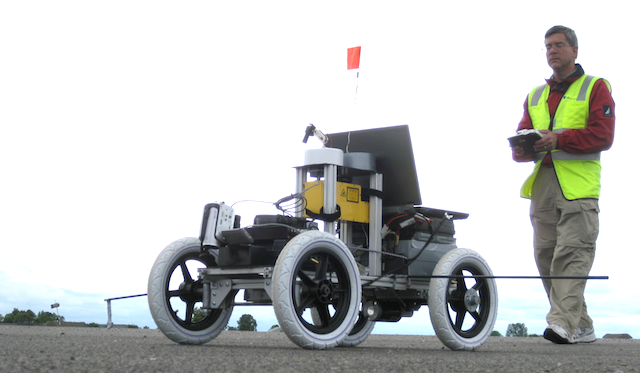

Detailed knowledge of your pavement’s texture is vital to understanding and improving friction. Transtec operates RoboTex, a unique, robotic-based texture-measuring device utilizing a line laser. RoboTex produces full 3-dimensional images that allow detailed and intuitive visualization of the surface texture.

A full suite of analytical metrics are also determined, including mean profile depth (MPD) according to ASTM E 1845 – 96 (Standard Practice for Calculating pavement Macrotexture Mean Profile Depth).

Texture in both the longitudinal and transverse directions is evaluated, especially useful for friction investigations in both the longitudinal and side directions. RoboTex meets ISO 13743-3, class DE profilometer.

There are many friction testing methods and devices for roads and runways. Some methods involve towing skid trailers while others are stationary, spot methods. Transtec can recommend the equipment and test methods best suited for your situation. If friction testing has already been accomplished, we can help you understand and interpret those results. Here is a list of some common friction testing methods, devices, and indices.

ASTM E 1911 Standard Test Method for Measuring Paved Surface Frictional Properties Using the Dynamic Friction Tester

ASTM E 965 Standard Test Method for Measuring Pavement Macro Texture Depth Using a Volumetric Technique

ASTM E 2157 Standard Test Method for Measuring Pavement Macro Texture Properties Using the Circular Track Meter

ASTM E 274 Standard Test Method for Skid Resistance of Paved Surfaces Using a Full Scale Tire

Standard Method of Test for Frictional Properties of Paved Surfaces Using a Full-Scale Tire

ASTM E 670 Standard Test Method for Side Force Friction on Pave Surfaces using the Mu-Meter

Sideway-force Coefficient Routine Investigation Machine

ISO 13473-3 Characterization of pavement texture by use of surface profiles — Part 3: Specification and classification of profilometers

ASTM E 1960 – 07 Standard Practice for Calculating International Friction Index of a Paved Surface

ASTM E 2100 – 04 Standard Practice for Calculating the International Runway Friction Index

British Standard BS 812:Part 114:1989 Testing aggregates – Method for determination of the polished-stone value.

CONTACT US

The Transtec Group engineers the best pavements in the world. Have a pavement problem? Give us a call—we’re good listeners.

© 2025 | The Transtec Group, Inc. | Privacy Policy